Exploring the Advantages of SLA Prototype Service in Modern Engineering

In the ever-evolving landscape of modern engineering, innovation and precision drive progress. From product development to industrial design, engineers and manufacturers constantly seek methods that deliver faster results with higher accuracy. Among the various 3D printing technologies available today, SLA prototype service has emerged as a game-changer. SLA, or Stereolithography Apparatus, is renowned for its ability to create highly detailed and smooth prototypes, offering engineers a dependable solution for testing and validating their designs before full-scale production.

The importance of SLA technology goes beyond simple prototyping—it bridges the gap between digital design and physical creation. Whether used in automotive, aerospace, medical, or consumer electronics, the precision and efficiency of SLA printing allow engineers to refine concepts rapidly. As industries lean toward faster innovation cycles and more complex designs, SLA prototype service continues to be at the forefront, empowering creators to push the boundaries of what’s possible in modern engineering.

Understanding the Fundamentals of SLA Prototype Service

At its core, SLA prototype service utilizes a process known as photopolymerization. In this method, a UV laser selectively cures liquid resin layer by layer to form a solid object. Each layer is precisely drawn by the laser, resulting in extremely accurate and detailed prototypes. Compared to other 3D printing technologies such as FDM (Fused Deposition Modeling) or SLS (Selective Laser Sintering), SLA offers smoother surfaces and finer resolution. This precision makes SLA ideal for applications that demand intricate features and tight tolerances—an essential aspect in engineering product validation.

Another defining feature of SLA is its versatility. A wide range of resins can be used to achieve different mechanical, thermal, and aesthetic properties. For instance, engineers can choose resins that mimic the look and feel of ABS plastic for functional prototypes or opt for clear resins to evaluate optical components. This adaptability allows SLA prototype service to cater to diverse engineering needs, from early design iterations to final pre-production models. Ultimately, it provides a tangible and accurate representation of complex designs before committing to expensive tooling or mass production.

High Precision and Surface Quality in Engineering Applications

One of the most significant advantages of SLA prototype service lies in its unmatched accuracy. The process can achieve layer thicknesses as fine as 25 microns, ensuring that even the smallest details are captured with precision. This level of accuracy is particularly beneficial for industries where dimensional fidelity is critical, such as aerospace and medical device engineering. When engineers can trust their prototypes to reflect exact measurements, it reduces the risk of costly errors in later development stages.

In addition to precision, the superior surface finish produced by SLA technology sets it apart from other 3D printing methods. Unlike FDM prints, which often require post-processing to smooth out layer lines, SLA parts come out of the printer with a near-polished surface. This makes them ideal for functional prototypes, aesthetic evaluations, and even end-use components. The smoothness not only enhances the visual appeal but also improves the aerodynamics and fit of mechanical assemblies. For modern engineering teams, SLA prototype service is synonymous with precision craftsmanship and professional-grade results.

Accelerating Product Development Through Rapid Prototyping

Speed and agility are crucial in today’s engineering and manufacturing environments. SLA prototype service plays a vital role in accelerating the product development cycle by offering rapid turnaround times. Engineers can quickly produce prototypes, test their functionality, and iterate on the design within days rather than weeks. This rapid prototyping capability allows teams to detect design flaws early and make informed adjustments before moving into production. The faster a prototype can be tested and improved, the more competitive a company becomes in bringing products to market.

Moreover, SLA printing enables parallel development processes. While one prototype is being tested, another can be printed with design modifications, ensuring a continuous feedback loop. This efficiency leads to reduced development costs and shorter time-to-market—two key advantages in fast-paced industries such as consumer electronics, automotive, and healthcare. The SLA prototype service model empowers engineering teams to move from concept to production with greater confidence and agility, reshaping how innovation unfolds in the modern era.

Cost Efficiency and Material Versatility in Engineering Projects

Although precision and speed are vital, cost-effectiveness remains a major concern in engineering projects. SLA prototype service offers a cost-efficient solution by eliminating the need for expensive tooling and molds during the early design stages. Instead of investing in costly manufacturing setups, engineers can 3D print accurate prototypes for testing and validation. This not only reduces upfront expenses but also minimizes material waste. Since the SLA process uses only the amount of resin necessary for each layer, it ensures efficient material utilization.

The versatility of materials available for SLA printing further enhances its value proposition. Engineers can choose from resins that simulate rubber-like flexibility, high heat resistance, or industrial-grade rigidity. This means a single SLA prototype service provider can accommodate various application needs—from functional mechanical parts to visually appealing presentation models. Such flexibility allows companies to test a range of design scenarios using different material properties, ultimately leading to more refined and reliable final products. By merging cost efficiency with material diversity, SLA technology supports smarter engineering decisions and sustainable innovation.

Real-World Applications of SLA Prototype Service in Modern Engineering

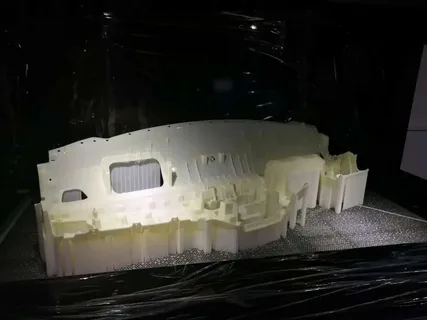

The influence of SLA prototype service spans across multiple industries, revolutionizing how engineers and designers approach product development. In the medical sector, for instance, SLA printing is used to create anatomical models, dental molds, and surgical guides with exceptional precision. Engineers in aerospace utilize SLA to produce lightweight yet durable components for testing aerodynamic efficiency. Similarly, the automotive industry leverages SLA for creating prototype parts, such as housings, fixtures, and interior components, enabling better fit and performance analysis before production.

Beyond these traditional fields, SLA technology is also gaining traction in consumer electronics, jewelry design, and even robotics. The ability to produce visually stunning and dimensionally accurate prototypes makes SLA an invaluable tool for creative professionals and engineers alike. As digital manufacturing continues to evolve, SLA prototype service is becoming a cornerstone of modern engineering workflows. It not only enhances design flexibility and product quality but also supports sustainable practices by reducing waste and optimizing production efficiency. This makes SLA a critical component of the engineering toolkit for the 21st century and beyond.

Conclusion

The role of SLA prototype service in modern engineering cannot be overstated. Its combination of accuracy, versatility, speed, and cost-efficiency makes it a cornerstone technology for innovation-driven industries. By transforming digital designs into high-fidelity physical models, SLA allows engineers to visualize, test, and refine concepts like never before. As industries increasingly demand precision and speed, SLA continues to offer a dependable bridge between imagination and production.

Looking ahead, advancements in photopolymer materials, automation, and large-format SLA printers will further expand its potential. Engineers can expect faster print times, stronger resins, and more sustainable manufacturing practices. Whether for intricate medical devices, lightweight aerospace components, or aesthetic product designs, SLA prototype service will remain an essential tool driving the next generation of engineering excellence. It is more than just a 3D printing method—it is a catalyst for creativity, precision, and innovation in the modern world.

Post Comment